Introduction:

Leak Tester is a kind of tester that use compression air to produce negative pressure by vacuum device to

test the seal capability and processing technique of soft plastic packaging material in food and

pharmaceutical industry. It also can test the specimen which has done the drop and compression test. The

product is designed and manufactured according to GB/T15171-94 (the Seal Testing Method for soft

packaging). ASTM D 3078 Standard Test Method for Determination of Leaks in Flexible Packaging

Working principle:

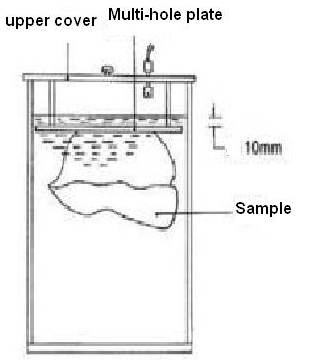

To vacuum the vacuum room and make the pressure difference between inside and outside of the specimen in the water. We can valuate the seal capability by observing the air permeability situation of the specimen.

Technical parameters:

Test Range : -0.9~0bar

Accuracy: 0.01 bar

·Vacuum: ≤0-(―90KPa)

·Veracity:1 degree

·Input air pressure: 0.2-0.5Mpa (customer self provide)

Air use : 70L/min

·Dimension of vacuum room: Φ280*320 mm

·Power: 220V, 50HZ

·Dimension: 31(B)×37(L)×50(H) cm

Work principle: air pressure difference between the inside and outside of the sample —- air expand — air leak— air new balance— air rate rise in the inside of the sample— air expand rate rise— sample receives bigger pressure— air leak stronger.