Introduction:

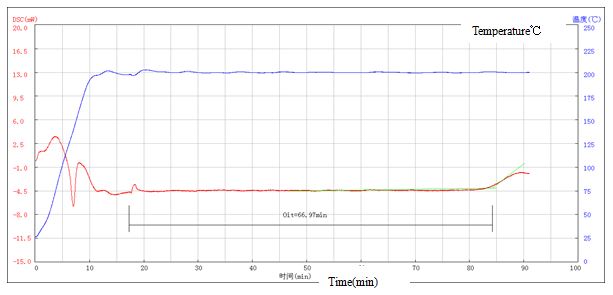

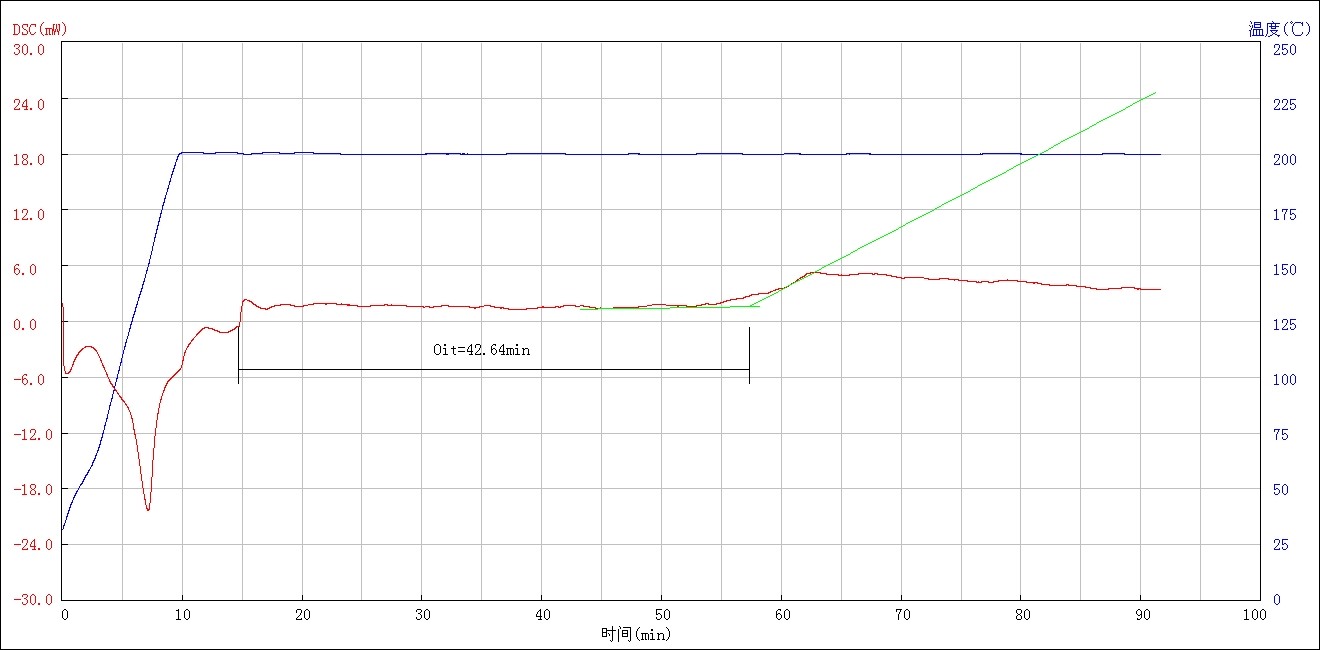

DSC is designed to determine the inner heat transition relating to temperature and heat flow, it is widely used in the field of polymer development, performance testing & quality control. DSC research and development includes the following field: glass transition temperature, melting point, cold crystallization, crystallization, phase transition, oxidation induction time (OIT).

Standards:

ISO/TR10837:1991, ASTM D3895-1998, ASTM E 967, ASTM E 968, ASTM E 793, ASTM D 3895, ASTM D 3417, ASTM D 3418, ISO 11357-6

Main Features:

- New designed oven structure ensures high resolution and good stability of base line

2. Air flow meter may control the air flow rate accurately; the test data can be recorded - It is bilateral control, may be controlled by both main frame and software.

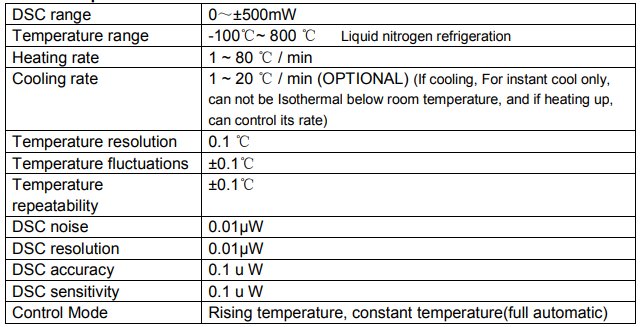

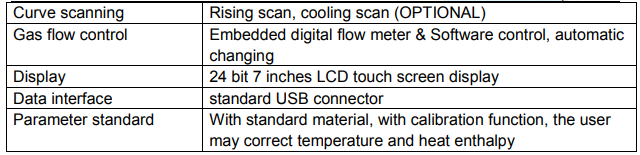

Technical parameters:

Packing List

Test Curves

Email:info@skzindustrial.com