This tester is applied to test the wear ability of vulcanized rubber. It tests the abrasion consumption in

certain testing range by the friction under certain tilt angle and load. The machine is designed according to GB/T 1689-1998: Rubber vulcanized—Determination of abrasion resistance (Akron machine) equal to ISO:

4661-1:1993, ISO 2481:1988, ISO 471:1983, ISO 1826:1981, with digital setting and displaying the times of

friction, automatically stop and integrate the host and controller.

Technical parameters:

1.tire suffered force: 26.7N (2.7kgf)

2.tire axis rotary speed: 76±2r/min

3.wheel axis speed: 33-35r/min

4.angle between the two axis: 0°~45°

5.power voltage: AC220V±10%

6.dimension: 600×480×400 (mm)

7.weight: 60kg

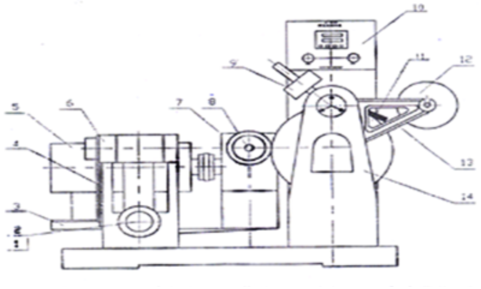

1. Angle adjust handwheel 2. Screw cap 3. Electromotor seat 4. Index 5. Electromotor 6. Angle adjust

bracket 7. Speed-down chest 8. Wheel and axle 9.Pressure adjust knob

10. Arithmometer 11. Grinding wheel 12. Poise 13. Grinding wheel bracket 14. Bracket

certain testing range by the friction under certain tilt angle and load. The machine is designed according to GB/T 1689-1998: Rubber vulcanized—Determination of abrasion resistance (Akron machine) equal to ISO:

4661-1:1993, ISO 2481:1988, ISO 471:1983, ISO 1826:1981, with digital setting and displaying the times of

friction, automatically stop and integrate the host and controller.

Technical parameters:

1.tire suffered force: 26.7N (2.7kgf)

2.tire axis rotary speed: 76±2r/min

3.wheel axis speed: 33-35r/min

4.angle between the two axis: 0°~45°

5.power voltage: AC220V±10%

6.dimension: 600×480×400 (mm)

7.weight: 60kg

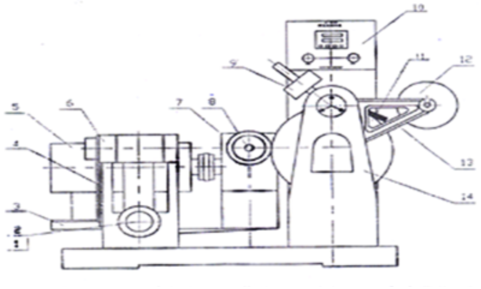

1. Angle adjust handwheel 2. Screw cap 3. Electromotor seat 4. Index 5. Electromotor 6. Angle adjust

bracket 7. Speed-down chest 8. Wheel and axle 9.Pressure adjust knob

10. Arithmometer 11. Grinding wheel 12. Poise 13. Grinding wheel bracket 14. Bracket

Email:info@skzindustrial.com