It is applicable in testing the leak capability of soft packaging, semi-rigid package, rigid packaging in food, beverage, pharmacy, etc industry. Through the test, it can well observe and evaluate the bottle cap or closed container’s seal craft and sealing property, provide scientific date for relative technical research.

Standard:

GB/T14803: Packaging volume aluminum caps of pilfer proof

GB/T17876: Packaging volume-Plastic pilfer proof closure

BB/T0025: 30/25mm plastic guard against theft bottle cap

GB17590: Easy open three cans

GB 10440-89: Cylindrical composite cans

ASTM D 3078 Standard Test Method for Determination of Leaks in Flexible Packaging

Working principle:

To vacuum the vacuum room and make the pressure difference between inside and outside of the specimen in the water. We can evaluate the seal capability by observing the air permeability situation of the specimen. It also greatly improves the accuracy of the seal test.

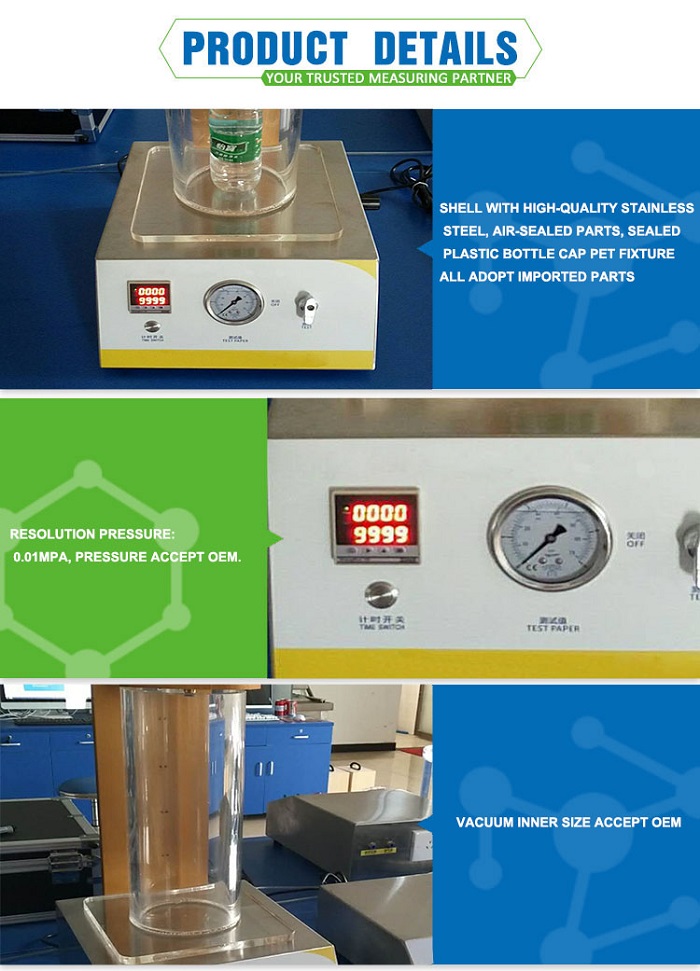

Feature:

Technical parameters:

| Test Range | 0–200KPa ( 0.2MPa Or 2Kgf)

(0.2MPa(2Kgf)—1.20Mpa accept OEM) |

| Pressure resolution | 0.01MPa |

| Time accuracy | <0.01% |

| Test chamber size | 200*200mm, 300*350mm, 400*400mm

accept OEM |

| Air pressure range | 86~106kPa |

| Air source | 0.15 ~ 1.5 Mpa

(air source pressure should larger than test pressure) |

| Environment temperature | 5~40℃ |

| Relative humidity | ≤80% |

| Power | 220V, 50HZ or 60HZ(grounding wire required) |

| Weight | 25 kg. |