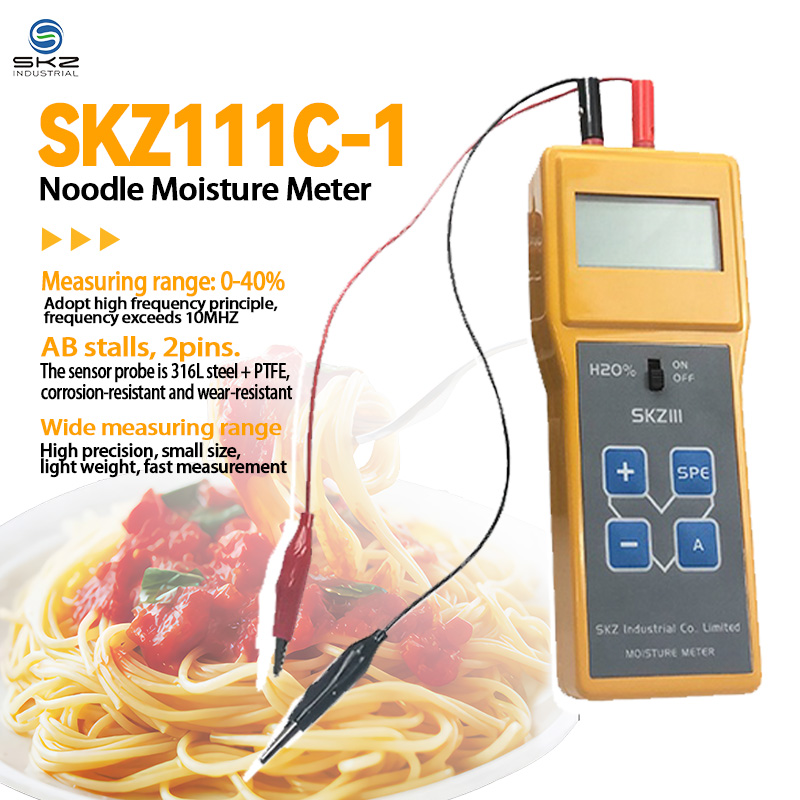

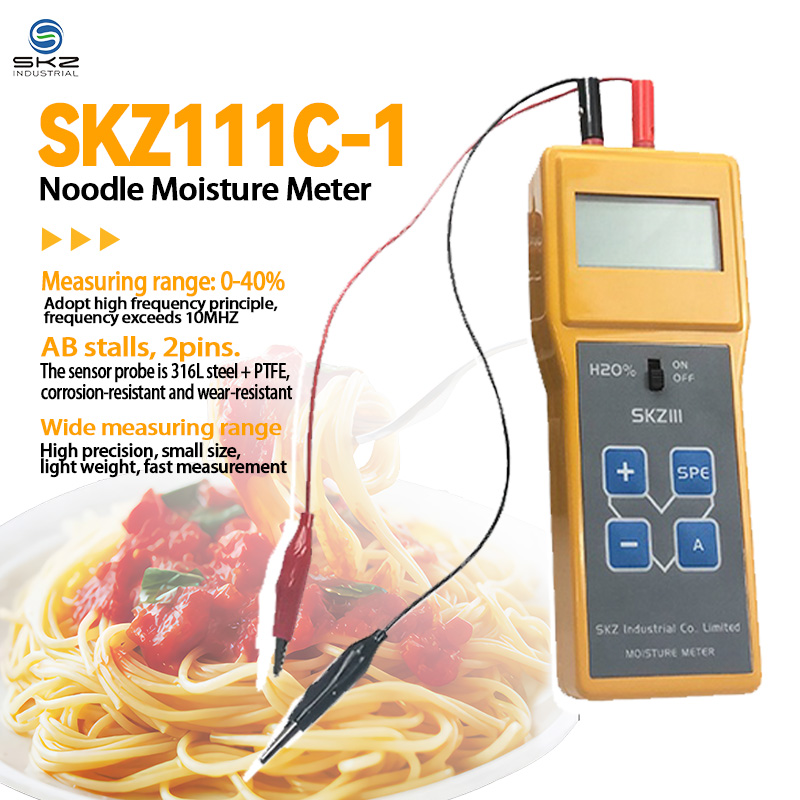

Food processing industries worldwide gain a precision tool with the release of the SKZ111C-1 Pasta Moisture Meter – a compact, high-performance device tailored to optimize pasta quality control. Designed for efficiency and durability, it addresses critical pain points in pasta production, from consistency to equipment longevity.

At its core, the SKZ111C-1 leverages a high-frequency principle with a frequency exceeding 10MHz, ensuring fast and reliable moisture detection. It boasts a broad measuring range of 0-40%, covering the full spectrum of pasta production needs – from fresh dough to dried spaghetti, penne, and beyond.

Precision is further enhanced by its robust sensor probe, crafted from 316L stainless steel and PTFE. This combination delivers exceptional corrosion resistance and wear resistance, standing up to repeated use with acidic, alkaline, or high-moisture pasta formulations (including those with tomato, garlic, or olive oil infusions).

The meter features AB stalls and 2-pin configuration, simplifying operation for on-site workers. Its small size and light weight enable easy portability, making it suitable for use on production lines, warehouses, or quality control labs.

Key benefits include high precision, rapid measurement speeds, and low maintenance – directly addressing industry frustrations like slow testing, inconsistent results, and probe degradation. For manufacturers, this translates to reduced waste, improved product uniformity (critical for texture and cooking time), and longer equipment lifespan.

Pasta moisture content is a make-or-break factor for texture, shelf life, and consumer satisfaction. Overly moist pasta risks spoilage, while dry formulations can lead to brittle, overcooked products. Traditional meters often struggle with accuracy, durability, or cumbersome design – gaps the SKZ111C-1 aims to fill.

“We engineered the SKZ111C-1 to meet the real-world demands of pasta production,” said a brand spokesperson. “Its combination of high-frequency accuracy, corrosion-resistant hardware, and user-friendly design ensures manufacturers can maintain quality standards without sacrificing efficiency.”

Ideal for small-scale artisanal producers and large industrial facilities alike, the SKZ111C-1 is now available for global orders. It aligns with food safety and quality control trends, emphasizing reliability and operational simplicity – critical for fast-paced food manufacturing environments.

What challenges do you face with pasta moisture testing? How would a durable, high-precision meter streamline your production? Share your thoughts in the comments below!